Growing Industrial Demand

One of the primary factors driving the growth of the ultrasonic flowmeter market is the increasing demand for efficient flow measurement systems across industrial applications. Industries such as oil and gas, chemical processing, and water management are experiencing rising pressure to optimize operations, reduce costs, and meet strict environmental regulations. Ultrasonic flowmeters offer non-invasive, accurate, and reliable flow measurement solutions that improve operational efficiency and ensure regulatory compliance.

In the oil and gas sector, for instance, accurate flow measurement is critical for pipeline monitoring and custody transfer, where errors in flow readings can result in significant financial losses. Ultrasonic flowmeters are ideal for these applications because they provide precise measurements without disrupting the flow process or requiring any mechanical alterations. As the demand for more sophisticated flow measurement systems rises, ultrasonic flowmeters have become the go-to solution for industries worldwide.

Technological Advancements and Innovations

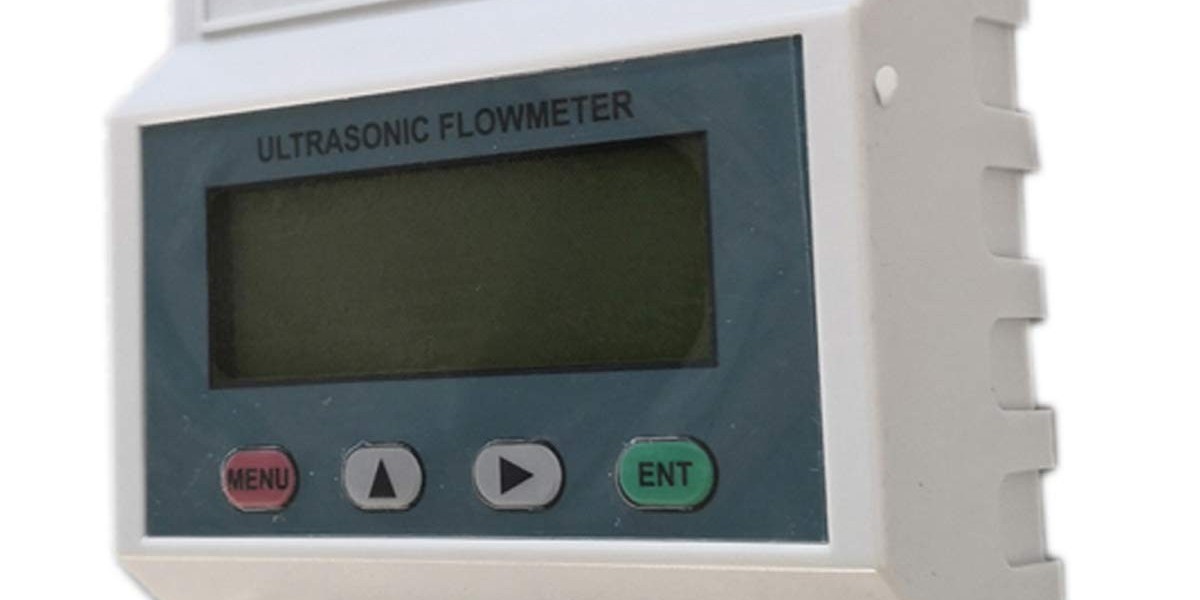

Technological advancements have played a significant role in the growth of the ultrasonic flowmeter market. Over the past decade, the development of more advanced sensors, digital signal processing, and multi-path measurement technologies has significantly improved the performance and versatility of ultrasonic flowmeters.

Innovations such as smart flowmeters, capable of real-time monitoring, data logging, and integration with Industrial Internet of Things (IIoT) systems, have opened up new possibilities for industries to optimize their operations. These flowmeters can now provide actionable insights, allowing operators to monitor performance remotely, predict maintenance needs, and troubleshoot problems without the need for on-site visits. These smart features make ultrasonic flowmeters an essential part of modern, automated industrial processes, further contributing to their market growth.

Rising Adoption in Emerging Markets

The increasing adoption of ultrasonic flowmeters in emerging markets is another key driver of market growth. As industrialization accelerates in regions such as Asia-Pacific, Latin America, and the Middle East, the need for efficient flow measurement solutions is growing. These regions are investing in infrastructure development and upgrading their industrial processes, and ultrasonic flowmeters are seen as an affordable and reliable solution for accurate flow measurement in these rapidly developing markets.

Countries like China, India, and Brazil are experiencing significant growth in their oil and gas, water treatment, and chemical industries, which are key sectors that rely on accurate flow measurement. The expanding demand for energy, water, and chemicals in these regions is propelling the adoption of ultrasonic flowmeters, driving market growth. Additionally, the push for greater energy efficiency and sustainability in these regions is encouraging industries to adopt advanced technologies like ultrasonic flowmeters to monitor and optimize their systems.

Environmental Regulations and Sustainability

As global environmental awareness rises, regulatory pressures on industries to reduce emissions and conserve resources have intensified. Ultrasonic flowmeters play a crucial role in helping industries meet stringent environmental regulations by providing accurate flow data necessary for emissions monitoring, water conservation, and resource management.

For instance, ultrasonic flowmeters are used extensively in water treatment plants to monitor and optimize water distribution systems. They help identify leaks, prevent water wastage, and improve the overall efficiency of the water supply chain. With increasing emphasis on sustainability and regulatory compliance, the adoption of ultrasonic flowmeters in industries like water management and wastewater treatment has grown significantly.

Cost-Effectiveness and Ease of Use

The cost-effectiveness and ease of use of ultrasonic flowmeters have further contributed to their market growth. Unlike traditional flow meters, which often require invasive installation, maintenance, and recalibration, ultrasonic flowmeters are non-intrusive and require minimal maintenance. Their installation is simple and does not require the flow system to be altered, making them an ideal choice for industries seeking a quick and cost-effective flow measurement solution.

In addition, the longevity of ultrasonic flowmeters contributes to their cost-effectiveness. As these devices have fewer moving parts than mechanical flow meters, they experience less wear and tear, reducing the need for frequent repairs and replacements. This durability and reliability make ultrasonic flowmeters a long-term investment, which further fuels their widespread adoption in industries around the world.

Market Challenges

Despite the impressive growth of the ultrasonic flowmeter market, there are a few challenges that could impact its future growth. The initial cost of high-end ultrasonic flowmeters can be prohibitive for small and medium-sized enterprises (SMEs), limiting their widespread adoption in certain industries. Additionally, the need for specialized expertise in installation, calibration, and maintenance can create barriers for some businesses.

Moreover, although ultrasonic flowmeters are highly accurate, they may face limitations in certain applications involving extremely low or high flow rates or in very turbulent fluid flows. Ongoing research and development efforts aim to address these limitations, further enhancing the applicability of ultrasonic flowmeters in diverse industries.

Conclusion

The ultrasonic flowmeter market is experiencing significant growth driven by technological advancements, rising industrial demand, and the increasing adoption of these devices in emerging markets. As industries continue to prioritize efficiency, accuracy, and sustainability, ultrasonic flowmeters will play a pivotal role in ensuring optimal flow measurement and operational efficiency. With continued innovation and improved accessibility, the market is poised for further expansion, offering a wealth of opportunities across various sectors.