Shape memory polymers are transforming industries by providing adaptive, versatile solutions to complex engineering challenges. These materials have the unique ability to return to a predetermined shape when exposed to specific external stimuli such as temperature, light, or electric fields. This remarkable property has led to an increasing demand for shape memory polymers across various sectors, including healthcare, aerospace, automotive, and electronics. Understanding the growing demand in these key industries highlights the potential for continued market expansion.

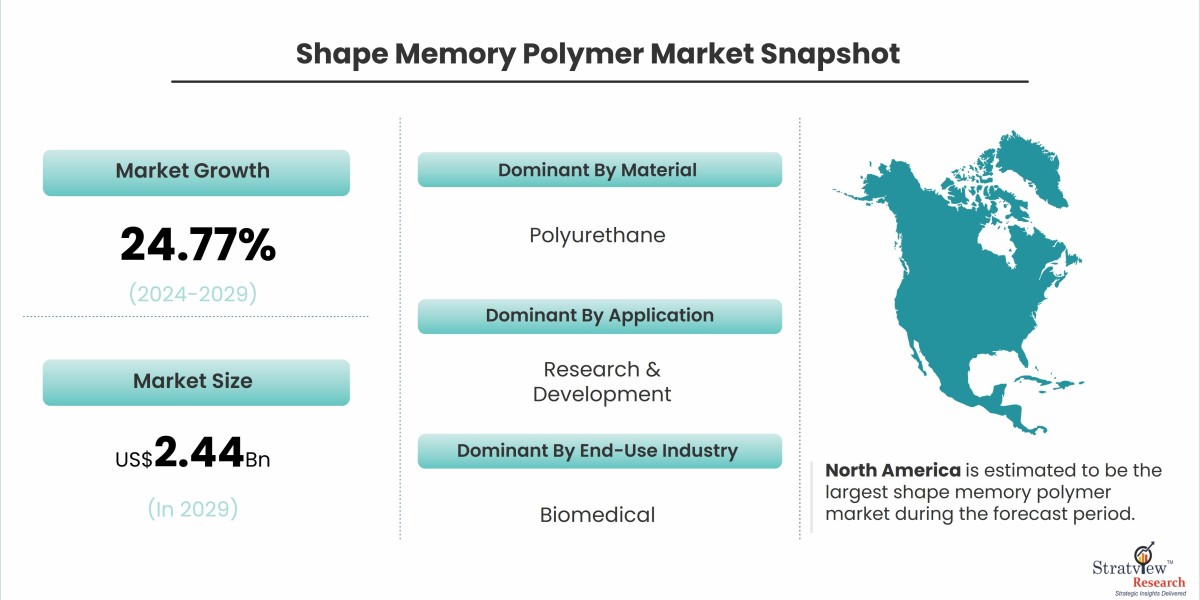

According to Stratview Research, the shape memory polymer market was estimated at USD 0.65 billion in 2023 and is likely to grow at a CAGR of 24.77% during 2024-2029 to reach USD 2.44 billion in 2029.

- Healthcare and Medical Devices

The healthcare industry is one of the largest drivers of demand for shape memory polymers. shape memory polymers are ideal for medical devices, particularly those used in minimally invasive procedures. Stents, sutures, and orthopedic implants made from shape memory polymers can expand, contract, or change shape inside the body in response to heat or pressure, making them perfect for applications where traditional rigid materials would be unsuitable. As the healthcare sector continues to prioritize non-invasive treatments and patient comfort, the demand for shape memory polymers in medical devices is expected to rise steadily. Furthermore, shape memory polymers offer customizable solutions for drug delivery systems, where controlled release can be triggered by environmental changes within the body.

- Aerospace and Defense

The aerospace industry is increasingly adopting shape memory polymers for their lightweight, durable, and adaptable properties. In applications such as morphing wings and deployable structures, shape memory polymers can adapt their shape in response to environmental conditions, improving aerodynamic efficiency and performance. Shape memory polymers can also be used in components that need to endure extreme temperature fluctuations or harsh conditions in space exploration. As the aerospace sector focuses on reducing weight to improve fuel efficiency and enhance performance, the use of shape memory polymers in aircraft and spacecraft is anticipated to grow, further driving demand.

- Automotive Industry

In the automotive sector, shape memory polymers are gaining traction due to their ability to create lightweight, adaptive materials that contribute to vehicle efficiency. Shape memory polymers are utilized in applications such as adaptive bumpers, energy-absorbing structures, and smart interiors that can change shape based on user preference or external factors like temperature. As manufacturers shift toward creating more energy-efficient and sustainable vehicles, the need for advanced materials like shape memory polymers will increase. These polymers also support the growing demand for smart car components, such as seats and dashboards that can adjust based on the user’s comfort.

- Electronics and Wearable Technology

SMPs are also becoming increasingly important in the electronics and wearable tech markets. Their flexibility and responsiveness make them ideal for applications in flexible displays, self-healing phone cases, and shape-shifting wearables. As consumer demand for wearable devices grows, shape memory polymers provide the durability and adaptability necessary for advanced electronics. Their ability to respond to environmental stimuli makes them valuable in the development of next-generation, smart electronics.

Conclusion

Shape memory polymers are rapidly gaining ground across various industries due to their unique properties and the growing demand for adaptive, efficient materials. From medical devices to aerospace and automotive components, shape memory polymers are becoming a critical part of innovation. As these industries continue to evolve, the demand for shape memory polymers is expected to increase, making them a key material in shaping the future of technology and manufacturing.