Silt fences are essential tools in construction projects that help protect the environment, particularly nearby waterways, from sedimentation. These fences play a critical role in ensuring that construction activities do not lead to water pollution, which can have serious ecological and environmental consequences. They are an effective means of controlling sediment runoff during construction and other land-disturbing activities. In this article, we will explore the various uses of silt fences in construction projects and how they contribute to the protection of nearby water bodies.

What Are Silt Fences and How Do They Work?

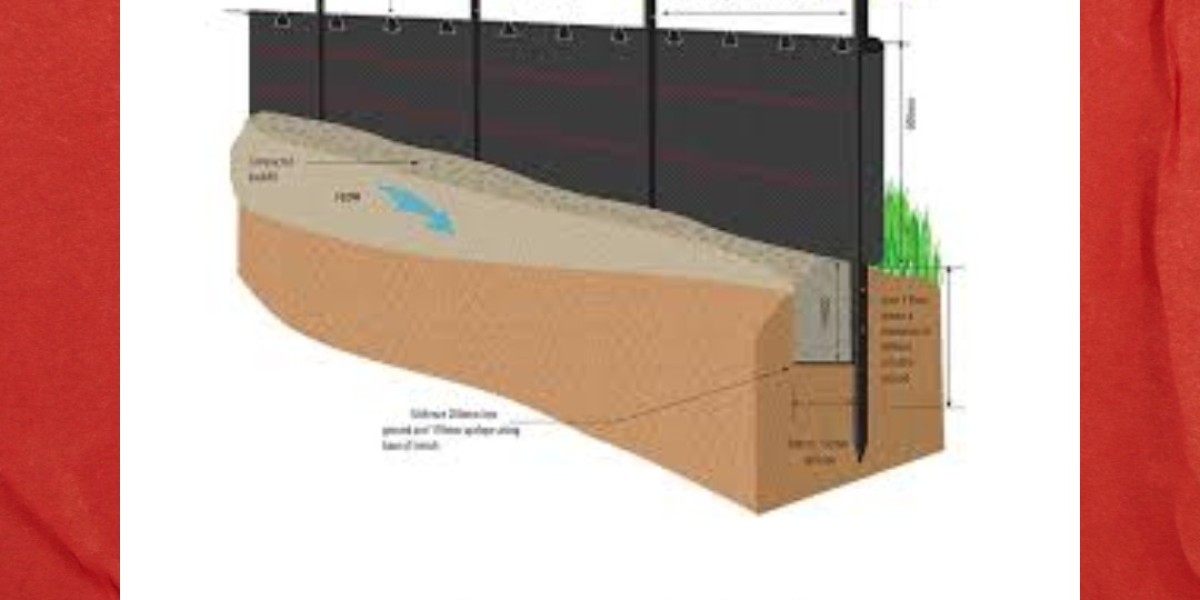

A silt fence is a temporary barrier made from permeable fabric, usually placed around construction sites, particularly near water bodies, to prevent sediment from being carried away by rain or wind. The fabric is typically supported by wooden or metal stakes, creating a structure that allows water to flow through while trapping sediment and debris. These fences are designed to capture loose particles of soil, sand, and other materials that could otherwise wash into nearby streams, rivers, or lakes. The key feature of a silt fence is its ability to filter runoff, allowing clean water to pass through while holding back larger particles of silt and sediment.

Importance of Silt Fences in Construction Sites Near Waterways

Construction projects, especially those involving excavation, grading, or land clearing, often disturb the soil, increasing the likelihood of sediment runoff. When this sediment enters nearby waterways, it can lead to water contamination, affecting the quality of water and disrupting aquatic ecosystems. Silt fences are crucial in such scenarios because they act as barriers that prevent sediment from being washed away into streams, rivers, or other bodies of water.

In many cases, regulations mandate the use of silt fences to meet environmental protection standards during construction activities. For example, in countries like India, construction projects near water bodies must comply with strict regulations to prevent sedimentation. The use of silt fences helps construction companies adhere to these regulations while minimizing their environmental impact. A Silt fence manufacturer in India plays an important role in providing these essential products, ensuring they meet the quality standards set by local and international environmental guidelines.

How Silt Fences Prevent Waterway Pollution

Silt fences are placed at strategic locations on construction sites, such as at the base of slopes, around the perimeter of the site, or near water bodies. By positioning the fence at these critical areas, the fence captures sediment before it has a chance to flow into waterways. As rainwater hits the soil, it may carry small particles of dirt, sand, and silt with it. When the water reaches the silt fence, it slows down, and the sediment is trapped by the fabric. The filtered water then passes through the fence, allowing clean water to flow while keeping harmful materials behind.

The ability of silt fences to filter out sediment makes them highly effective in preventing the degradation of water quality. Excessive sediment in water bodies can smother aquatic life, reduce oxygen levels, and disrupt the food chain. By using silt fences, construction companies can significantly reduce the risk of sediment pollution, contributing to cleaner, healthier waterways.

Advantages of Using Silt Fences Over Other Sediment Control Methods

Silt fences offer several advantages over other sediment control measures, making them the preferred choice in many construction projects. One of the main benefits is their cost-effectiveness. Silt fences are relatively inexpensive to install and maintain, especially when compared to other sediment control solutions such as sediment ponds or traps. These fences can cover large areas of land, making them ideal for both small and large-scale construction projects.

Another advantage of silt fences is their simplicity and ease of installation. Unlike more complex systems that require heavy equipment or specialized labor, silt fences can be quickly and easily set up by a small team of workers. The lightweight materials used in the construction of the fences make them easy to transport and handle, making them a convenient option for construction companies.

Silt fences are also versatile and adaptable. They can be used in a variety of construction settings, from residential and commercial sites to road construction and large infrastructure projects. Their flexibility allows them to be used in different types of terrain, including slopes, flat land, and areas with high water flow.

How Silt Fences Help Construction Projects Meet Environmental Standards

In many regions, including India, construction projects are required to meet strict environmental standards, particularly when working near water bodies. These standards are designed to protect water quality, aquatic ecosystems, and natural habitats from the harmful effects of sedimentation. Silt fences play a crucial role in helping construction companies comply with these regulations by providing an effective means of controlling sediment runoff.

The use of silt fences helps ensure that construction projects meet local environmental laws and avoid potential fines or legal consequences. A silt fence manufacturer in India understands the regulatory requirements and produces fences that meet the necessary standards for quality and performance. By using high-quality silt fences, construction companies can demonstrate their commitment to environmental stewardship while minimizing their impact on nearby waterways.

Selecting the Right Silt Fence for a Construction Site

Choosing the right silt fence for a construction site depends on several factors, including the size of the site, the type of construction work being done, and the specific environmental conditions of the area. Different types of silt fences are available, each designed for specific applications. For example, some silt fences are designed for use in low-lying areas with little water flow, while others are intended for high-flow areas where more robust protection is needed.

When selecting a silt fence, it is important to consider factors such as the strength of the fabric, the spacing between stakes, and the overall durability of the fence. A reliable silt fence manufacturer or Silt fence exporters can provide guidance on selecting the right product for a specific project, ensuring that the fence will perform effectively in preventing sediment runoff.

The Role of Silt Fence Manufacturers and Exporters

Silt fence manufacturers play a key role in providing construction companies with high-quality products that meet environmental standards. In India, silt fence manufacturers produce a range of products that are specifically designed to withstand the harsh conditions of construction sites. These fences are made from durable materials such as woven geotextile fabric, which is resistant to UV degradation and can endure exposure to the elements for extended periods.

Silt fence exporters also play a vital role in making these products available to international markets. By exporting silt fences, manufacturers can help construction companies around the world protect their local waterways and meet environmental regulations. Whether a construction site is located in India, the Middle East, or any other part of the world, high-quality silt fences are crucial for minimizing the environmental impact of construction projects.

Conclusion

Silt fences are essential tools in construction, providing a simple yet effective means of protecting nearby waterways from sedimentation. By trapping sediment and preventing it from entering streams, rivers, and lakes, silt fences help ensure water quality is maintained throughout construction activities. The use of silt fences is not only a cost-effective solution but also an environmentally responsible one. For construction companies looking to comply with environmental regulations, partnering with a trusted Silt fence manufacturer or exporter is key to ensuring that their projects meet the necessary standards for sediment control.

Frequently Asked Questions (FAQs)

1. What should I look for when purchasing silt fences?

When purchasing silt fences, it’s important to consider the material quality, durability, and the manufacturer’s reputation. Look for fences made from UV-resistant, woven geotextile fabric, as these are designed to withstand weather elements and provide effective sediment control. A reliable silt fence manufacturer or exporter can provide guidance on the best products for specific construction needs.

2. How much do silt fences cost?

The cost of silt fences varies depending on the material, size, and supplier. Generally, they are affordable, with prices ranging from a few dollars per linear foot to higher costs for premium or custom-designed fences. The cost may also vary based on the geographic location and the silt fence manufacturer.

3. Can silt fences be used in residential construction?

Yes, silt fences can be used in residential construction to control sediment runoff, especially if the construction site is near a water body or if there are significant land disturbances. Homebuilders often use silt fences to comply with local environmental regulations and prevent water contamination