The conductive polymer coating market is experiencing significant developments driven by the growing demand for innovative, sustainable, and high-performance materials across various industries. Conductive polymer coatings combine the electrical conductivity of metals with the flexibility and lightweight characteristics of polymers, making them essential in sectors such as electronics, automotive, healthcare, and energy. Recent innovations in this field have focused on improving performance, expanding applications, and enhancing sustainability. Below are some key recent developments in the conductive polymer coating market.

1. Integration of Advanced Nanomaterials

Recent advancements in conductive polymer coatings have seen the integration of nanomaterials such as carbon nanotubes (CNTs), graphene, and silver nanowires. These materials enhance the conductivity, mechanical properties, and overall performance of the coatings. Graphene, in particular, has gained attention for its high electrical conductivity, flexibility, and lightweight nature. It enables the creation of highly efficient and durable coatings for wearable electronics, flexible displays, and energy storage devices. These developments have expanded the potential applications of conductive polymer coatings in industries like smart textiles, healthcare devices, and automotive electronics.

2. Sustainable and Eco-Friendly Solutions

As the global demand for sustainable materials increases, the conductive polymer coating market has seen a shift towards more eco-friendly and bio-based coatings. Traditional coatings often contain volatile organic compounds (VOCs) and other harmful chemicals, but manufacturers are now focusing on creating coatings that are water-based and bio-based. These coatings help reduce environmental impact while offering enhanced performance. Water-based conductive polymer coatings are particularly popular in industries that require high-quality coatings without compromising on environmental safety.

In addition, bio-based polymers derived from renewable sources like plant oils and biodegradable materials are increasingly being used in the formulation of conductive coatings. This shift to sustainable solutions aligns with the growing need for environmentally responsible manufacturing practices and offers a competitive edge in markets with stringent environmental regulations.

3. Flexible Electronics and Wearable Devices

Flexible electronics have been a key driver of recent developments in the conductive polymer coating market. Wearable devices, smart textiles, and stretchable electronics require conductive coatings that can maintain their performance while remaining flexible and lightweight. Conductive polymer coatings are increasingly being used to meet these demands, enabling the development of flexible sensors, printed electronics, and integrated circuits that can be worn on the body or incorporated into fabrics.

Recent innovations have led to the development of stretchable conductive coatings that retain their conductivity even when stretched or deformed. These coatings are ideal for health monitoring systems, smart clothing, and fitness trackers, which need to conform to the human body and operate reliably in varying conditions.

4. Electromagnetic Interference (EMI) Shielding

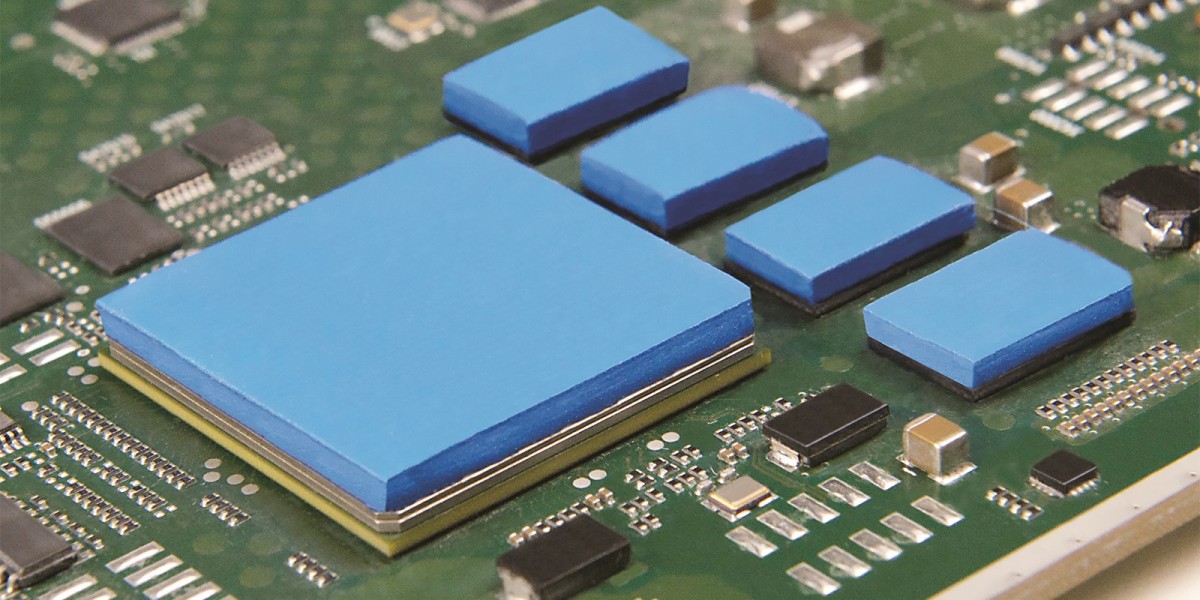

The demand for electromagnetic interference (EMI) shielding in electronic devices has also contributed to recent developments in the conductive polymer coating market. As electronic devices become more compact and interconnected, there is an increasing need to prevent electromagnetic waves from interfering with the operation of sensitive components. Conductive polymer coatings are increasingly being used to provide effective EMI shielding in a range of applications, from smartphones to automotive electronics and medical devices.

Recent developments have led to the creation of thin, lightweight coatings that provide superior EMI shielding properties without adding significant weight or bulk to the devices. This has led to the growth of the smart electronics market, where such coatings are used in everything from wireless communication devices to electronic medical equipment.

5. 3D Printing and Custom Coating Solutions

The advent of 3D printing has opened new possibilities for the production of conductive polymer coatings. 3D printing allows manufacturers to create custom-designed coatings that can be precisely applied to complex geometries and surfaces. This is particularly useful in industries like automotive and aerospace, where specialized coatings are required for custom parts and components.

Recent innovations in conductive ink for 3D printing have made it possible to create fully functional printed electronics, circuitry, and coated surfaces in a highly efficient and cost-effective manner. This technology is expected to revolutionize the production of flexible electronics and smart devices in the coming years.

6. Growth in Biomedical Applications

The biomedical sector is witnessing a rise in the adoption of conductive polymer coatings for applications in biosensors, implantable devices, and neurostimulation therapies. Conductive polymers are biocompatible and can be tailored to offer both electrical conductivity and mechanical flexibility, making them ideal for use in medical devices that require long-term implantation.

Recent developments have focused on improving the biocompatibility of conductive polymer coatings, making them suitable for direct contact with biological tissues without causing adverse reactions. This innovation is enabling the creation of advanced medical devices for monitoring and treating chronic conditions, such as neurological disorders and cardiac diseases.

Conclusion

The conductive polymer coating market is evolving rapidly due to technological advancements, growing demand for sustainability, and the rise of new applications across diverse industries. The integration of advanced nanomaterials, eco-friendly formulations, flexible electronics, and EMI shielding are among the key innovations driving market growth. As the world moves toward smart technologies, wearable devices, and green manufacturing, conductive polymer coatings are poised to play a crucial role in shaping the future of industries ranging from electronics to healthcare. The market will continue to evolve as new developments further expand the capabilities and applications of these versatile materials.