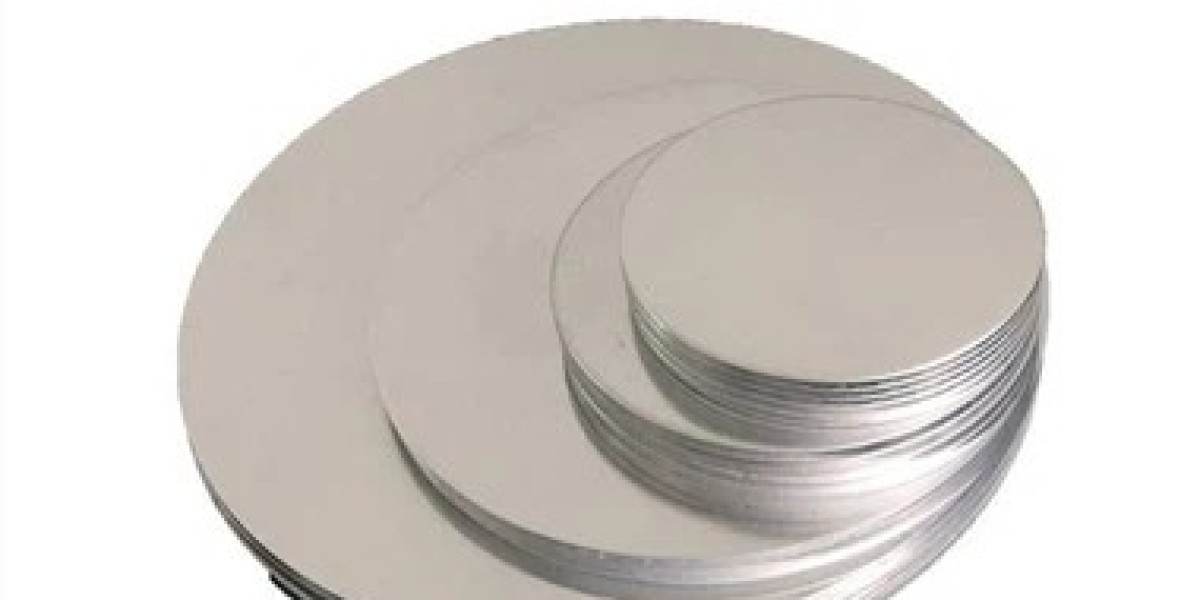

The aluminum slugs market has been steadily gaining attention across various industries, driven by the growing demand for lightweight and cost-effective materials. These slugs, which are precision-formed pieces of aluminum, serve as the foundation for products ranging from beverage cans to automotive components and even aerospace parts. As the demand for sustainable and high-performance materials increases, the aluminum slugs market has been evolving rapidly to cater to diverse needs. In this market analysis, we explore key trends, factors driving growth, challenges, and future prospects.

Market Drivers and Growth Trends

One of the primary drivers for the aluminum slugs market is the increasing demand for aluminum in lightweight applications. Aluminum is inherently a low-density metal, making it ideal for industries where weight reduction is a critical factor. The automotive sector, in particular, has been one of the largest consumers of aluminum slugs. With the push towards electric vehicles (EVs) and the need for lighter components to improve fuel efficiency, the demand for aluminum slugs in automotive manufacturing is expected to grow significantly.

Furthermore, the beverage industry continues to be a key market for aluminum slugs, particularly for the production of aluminum cans. As consumer preferences shift towards sustainable packaging solutions, aluminum cans are increasingly being favored due to their recyclability and lower environmental footprint. This trend is expected to further drive the demand for aluminum slugs, as beverage manufacturers seek reliable sources of aluminum for can production.

The aerospace industry, another important sector, is also contributing to the demand for aluminum slugs. Lightweight and durable components are essential in aerospace applications to enhance fuel efficiency and overall performance. As air travel continues to expand, manufacturers are investing in aluminum-based materials to meet these requirements, which will bolster the aluminum slugs market in the coming years.

Technological Advancements and Innovations

Technological innovations in aluminum processing are playing a significant role in shaping the market landscape. Advanced techniques for aluminum slugs production, such as precision forming, extrusion, and stamping, have allowed manufacturers to meet the growing demand for high-quality slugs with improved performance characteristics. Additionally, innovations in recycling technologies are helping companies reduce production costs and enhance the sustainability of aluminum products, making them more attractive to eco-conscious consumers and businesses alike.

The development of high-strength aluminum alloys is another notable trend. These alloys offer superior performance in demanding applications such as aerospace and automotive manufacturing. As manufacturers continue to explore new alloys and improve existing ones, the demand for specialized aluminum slugs is expected to increase, further fueling market growth.

Market Challenges and Competitive Landscape

Despite the promising growth prospects, the aluminum slugs market faces several challenges. One of the key issues is the fluctuating price of aluminum, which can significantly impact production costs. Since aluminum is a commodity metal, its prices are influenced by various factors, including global supply and demand dynamics, geopolitical tensions, and trade policies. Manufacturers in the aluminum slugs market must carefully manage these price fluctuations to maintain profitability.

The market is characterized by intense competition, with numerous players vying for market share. This has led to price pressure, particularly in regions where demand is high but profit margins are relatively low. To stay competitive, companies are focusing on innovation, expanding their product portfolios, and adopting efficient production processes to lower costs and improve product quality.

Another challenge is the environmental impact of aluminum production. While aluminum is highly recyclable, the energy-intensive process of refining and producing aluminum slugs can result in significant carbon emissions. As sustainability becomes a greater priority for industries worldwide, aluminum slugs manufacturers are under increasing pressure to adopt greener practices, such as utilizing renewable energy sources and improving recycling methods.

Future look

The aluminum slugs market is poised for continued growth, with key industries such as automotive, aerospace, and packaging driving demand. The increasing adoption of lightweight materials in vehicle manufacturing, coupled with the growing focus on sustainability, presents significant opportunities for market players. Additionally, advancements in manufacturing technologies and the development of high-performance alloys will further expand the scope for aluminum slugs in high-end applications.

However, the market will need to navigate several challenges, including price volatility and environmental concerns, in order to sustain its growth. Companies that can effectively address these issues while innovating in product development and improving operational efficiency will be well-positioned to capitalize on emerging opportunities.