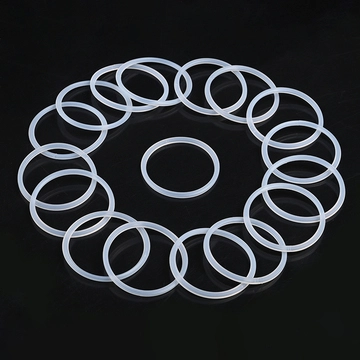

Silicone seal rings are essential components used in various applications, including automotive, aerospace, and industrial machinery. These rings are made from silicone rubber, a material known for its flexibility, durability, and resistance to extreme temperatures. Understanding the thermal stability of silicone seal rings is crucial for ensuring their performance and longevity in demanding environments.

Importance of Thermal Stability

Thermal stability refers to a material's ability to maintain its properties when exposed to high temperatures. For silicone sealing ring, thermal stability is vital because they often operate in environments where temperature fluctuations can occur. If a seal ring loses its integrity due to thermal degradation, it can lead to leaks, failures, and costly repairs. Therefore, evaluating the thermal stability of silicone seal rings is essential for their reliable performance.

Factors Affecting Thermal Stability

Several factors influence the thermal stability of silicone seal rings. The composition of the silicone rubber, including the type of fillers and additives used, plays a significant role. High-quality silicone compounds are designed to withstand elevated temperatures without losing their mechanical properties. Additionally, the manufacturing process, such as curing and molding, can affect the thermal stability of the final product.

Testing Methods for Thermal Stability

To evaluate the thermal stability of silicone seal rings, various testing methods are employed. One common method is the thermal aging test, where seal rings are exposed to high temperatures for extended periods. This test helps determine how the material behaves under thermal stress and identifies any changes in physical properties. Other methods include differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), which provide insights into the thermal transitions and decomposition of the material.

Applications Requiring High Thermal Stability

Silicone seal rings are used in applications that demand high thermal stability. For instance, in the automotive industry, these rings are often found in engines and transmission systems, where they are exposed to high temperatures and pressures. Similarly, in the aerospace sector, silicone seal rings are used in fuel systems and hydraulic components, where thermal stability is critical for safety and performance. Understanding the thermal stability of silicone seal rings in these applications is essential for ensuring their reliability.

Advantages of Silicone Seal Rings

Silicone seal rings offer several advantages over other materials. Their excellent thermal stability allows them to perform well in extreme conditions. Additionally, silicone rubber is resistant to UV radiation, ozone, and various chemicals, making it suitable for outdoor and harsh environments. These properties contribute to the longevity and effectiveness of silicone seal rings, reducing the need for frequent replacements.

Limitations of Silicone Seal Rings

Despite their many advantages, silicone seal rings also have limitations. One of the primary concerns is their performance at very low temperatures. While silicone rubber excels in high-temperature applications, its flexibility can decrease in extreme cold, potentially leading to seal failure. Additionally, silicone seal rings may not be suitable for applications involving certain aggressive chemicals, which can degrade the material over time.

Innovations in Silicone Seal Ring Technology

Recent advancements in silicone seal ring technology have focused on enhancing thermal stability and overall performance. Manufacturers are developing new silicone compounds with improved heat resistance and mechanical properties. These innovations aim to meet the growing demands of industries that require reliable sealing solutions in challenging environments. Continuous research and development in this field are essential for improving the performance of silicone seal rings.

Conclusion

In conclusion, the thermal stability of silicone seal rings is a critical factor in their performance and reliability. Understanding the factors that affect thermal stability, testing methods, and applications requiring high thermal stability is essential for manufacturers and users alike. While silicone seal rings offer numerous advantages, it is important to consider their limitations and ongoing innovations in technology. By exploring the thermal stability of silicone seal rings, industries can ensure the effectiveness and longevity of these vital components in various applications