The welding consumables market plays a vital role in industrial development, underpinning sectors like automotive, construction, oil and gas, and manufacturing. Welding consumables are materials that facilitate the joining of metals by providing a filler or flux during the welding process. These products are essential in ensuring durability, precision, and reliability in welded structures. The market is characterized by continuous innovation, diverse applications, and dynamic industry demands.

Key Market Segments

The welding consumables market is segmented based on product type, welding technique, and application.

1. Product Type:

This category includes filler materials such as flux-cored wires, solid wires, and coated electrodes. Flux-cored wires are gaining popularity due to their efficiency and versatility, particularly in high-strength applications. Solid wires remain a staple in industries requiring consistent and precise welds, while coated electrodes are widely used in manual welding operations due to their adaptability.

2. Welding Technique:

Techniques like arc welding, resistance welding, and oxy-fuel welding dominate the market. Arc welding, including MIG, TIG, and SMAW, holds a significant share due to its wide applicability and cost efficiency. Resistance welding is preferred in automotive and electronics industries for its speed and minimal distortion. Oxy-fuel welding, though less prevalent, remains relevant in certain niche applications and repair work.

3. Application:

Welding consumables find applications in multiple industries:

- Automotive: With the rise of electric vehicles and lightweight materials, the demand for advanced welding consumables has increased.

- Construction: Infrastructure projects drive the need for robust welding solutions to ensure safety and longevity.

- Oil and Gas: The sector relies on high-performance consumables capable of withstanding extreme conditions and corrosion.

- Shipbuilding and Aerospace: Precision and strength are critical, necessitating premium-grade consumables.

Emerging Trends

The welding consumables market is witnessing significant transformations driven by technological advancements and changing industry demands:

1. Automation in Welding Processes:

The adoption of automated welding systems is reshaping the industry. These systems enhance efficiency, reduce human error, and improve output quality. Consequently, consumables compatible with robotic welding systems are gaining traction.

2. Shift Toward Sustainability:

Eco-friendly welding consumables are emerging as a response to stricter environmental regulations. Low-fume electrodes and recyclable materials are examples of products aligning with green initiatives.

3. Growing Demand for Lightweight Materials:

As industries prioritize lightweight and high-strength materials like aluminum and composites, consumables designed to cater to these materials are gaining prominence.

4. Technological Integration:

Innovations such as advanced coatings, self-cleaning fluxes, and consumables tailored for specialized applications are revolutionizing the market. These developments cater to niche needs while improving welding efficiency and reducing waste.

Challenges and Opportunities

Despite its growth potential, the welding consumables market faces challenges like fluctuating raw material prices and the need for skilled labor. However, these challenges present opportunities for innovation, such as the development of cost-effective alternatives and training programs to upskill workers. Additionally, the rise in infrastructure projects and industrialization in emerging economies offers a significant growth avenue.

Conclusion

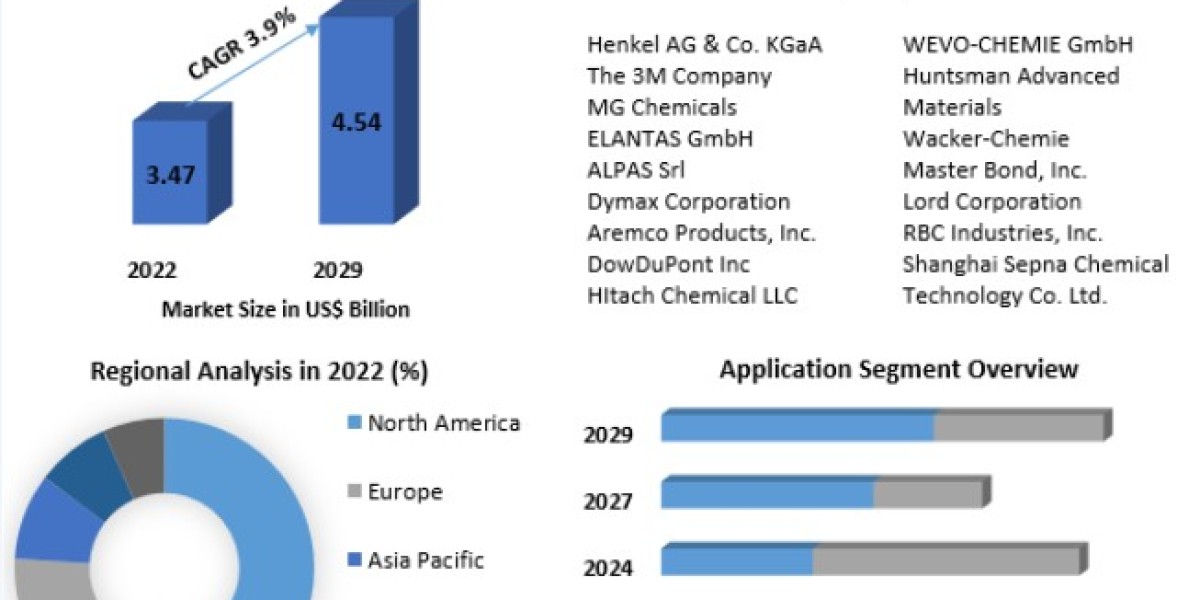

The welding consumables market is poised for steady growth, driven by technological advancements, evolving industry demands, and the increasing adoption of sustainable practices. By adapting to emerging trends and overcoming challenges, the market continues to innovate and support industrial progress across various sectors.