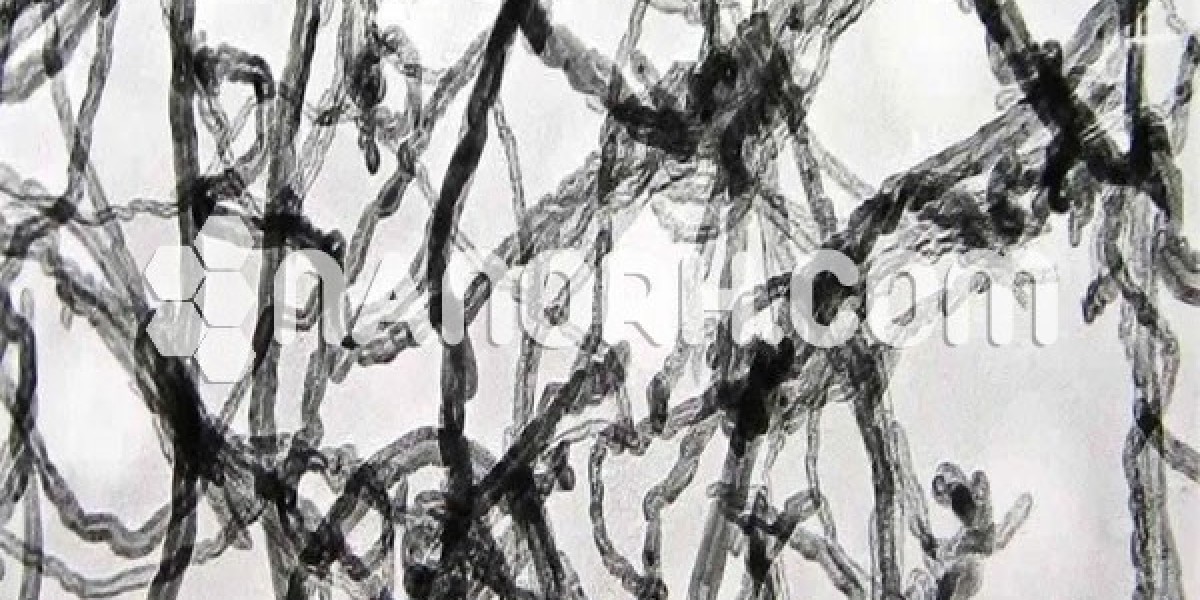

The MWCNTs are increasingly gaining attention from engineers in each field of materials science, mechanical engineering, and electronics.The cylindrical structures, which compose multiple layers of graphene sheets rolled concentrically around one another, give a unique combination of high tensile strength, lightweight properties, and excellent electrical and thermal conductivity, which features make the Multi walled Carbon Nanotubes offer solutions to common engineering challenges in ways previously unavailable with conventional materials.

Material Strength and Toughness

The greatest challenge of engineering is achieving a high material strength unrelated to weight. Traditional materials, metals, and polymers are generally strong and weak except in a few cases, which can be seen as both very strong and light. Multi walled Carbon Nanotubes provide excellent solutions for the same. Better tensile strengths at a hundred times stiffer than steel yet weighing only a fraction of the same made them highly ideal for reinforcing composite materials.

Engineered by the incorporation of MWCNTs into polymers or ceramics, lightweight composites that are much stronger and tougher have been developed. This is highly applied in the aerospace and automotive sectors, where the weight needs to be reduced without losing the structural integrity. For example, in composites reinforced by MWCNT, the structure stays resilient under extreme environmental conditions and high levels of mechanical strain. It assures the aerospace parts and vehicle structure of a long and reliable lifetime.

Electrical Conductivity

Multi walled Carbon Nanotubes exhibit yet another promising benefit with regard to electrical conductivity. The most conductive material is inherently made from metals such as copper or aluminium and suffers from inherent problems of weight and corrosion. MWCNTs offer the same level of conductivity with improved strength and weight. Engineers can thus replace or supplement metal-based conductors in the structure with MWCNTs, which, in turn, leads to an overall reduction in weight without impacting the electrical integrity of the circuitry.

MWCNTs have found application in electronic applications, mainly through the creation of more efficient, durable circuit boards and connectors. The nanoscale dimensions also play a promising role in miniaturized components in electronic devices, like transistors and sensors. Their high electron mobility enhances signal transmission in electronic systems with high-speed performance.

Thermal Management Enhancement

One of the biggest challenges in electronics and machine science involves dealing with heat. In machines, components are constantly becoming smaller and devices much stronger, creating an increasingly large challenge when it comes to heat management. Conventional materials have little conductive thermal properties that can help displace heat very efficiently. Here, multi walled carbon nanotubes are quite significant because they have far better thermal conductivity than copper.

From an engineering perspective, MWCNTs are implanted into composite materials and composed into high-performing dissipating systems for electronic devices in cooling down with less overheating. An example of TIMs is in computers and mobile phones, which depend upon the use of MWCNTs to control the suitable temperatures in which performance and lifespan are improved.

Future Potential and Environmental Benefits

In addition to a solution for the engineering problem, MWCNTs also possess an environmental advantage. Their use in different applications decreases the demand for metals, and these metals lower the weight of materials, which then decreases the energy needed to manufacture and transport.

Furthermore, because of MWCNT reinforced composites’ durability, products become solid and last longer, thereby reducing waste that is eventually generated with time.

Source: https://guest-post.org/how-multi-walled-carbon-nanotubes-can-solve-common-engineering-problems/