The electrostatic discharge packaging market plays a pivotal role in safeguarding sensitive electronic components against the damaging effects of electrostatic discharge, a common issue in industries such as electronics, automotive, telecommunications, and aerospace. As the global electronics industry continues to expand and innovate, the demand for effective ESD protection has surged, resulting in significant developments within the market.

Market Overview:

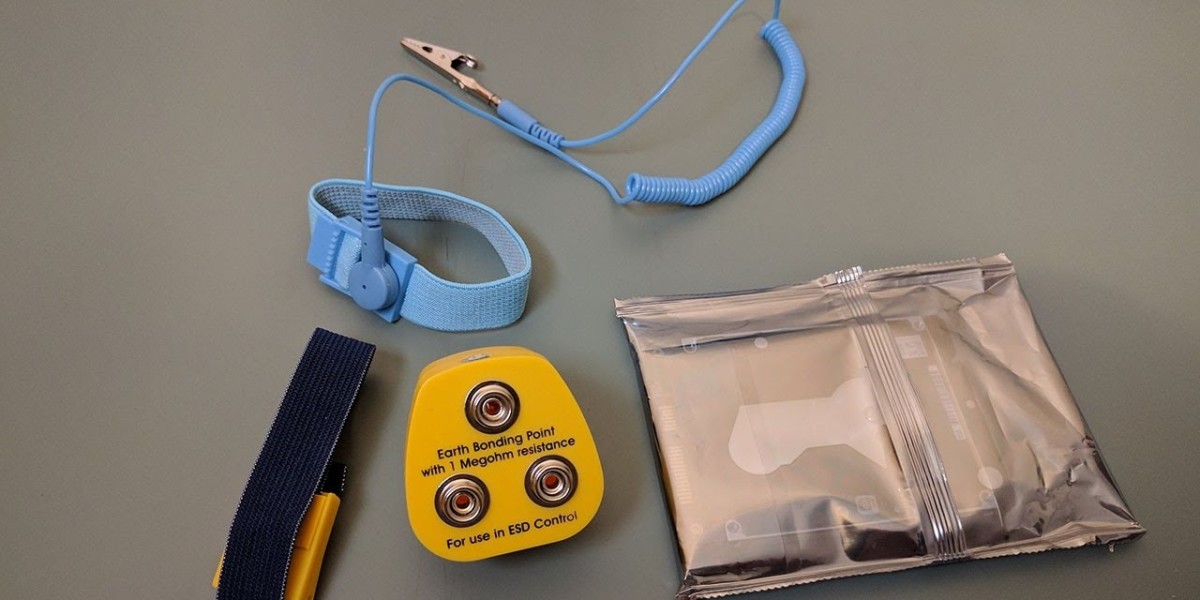

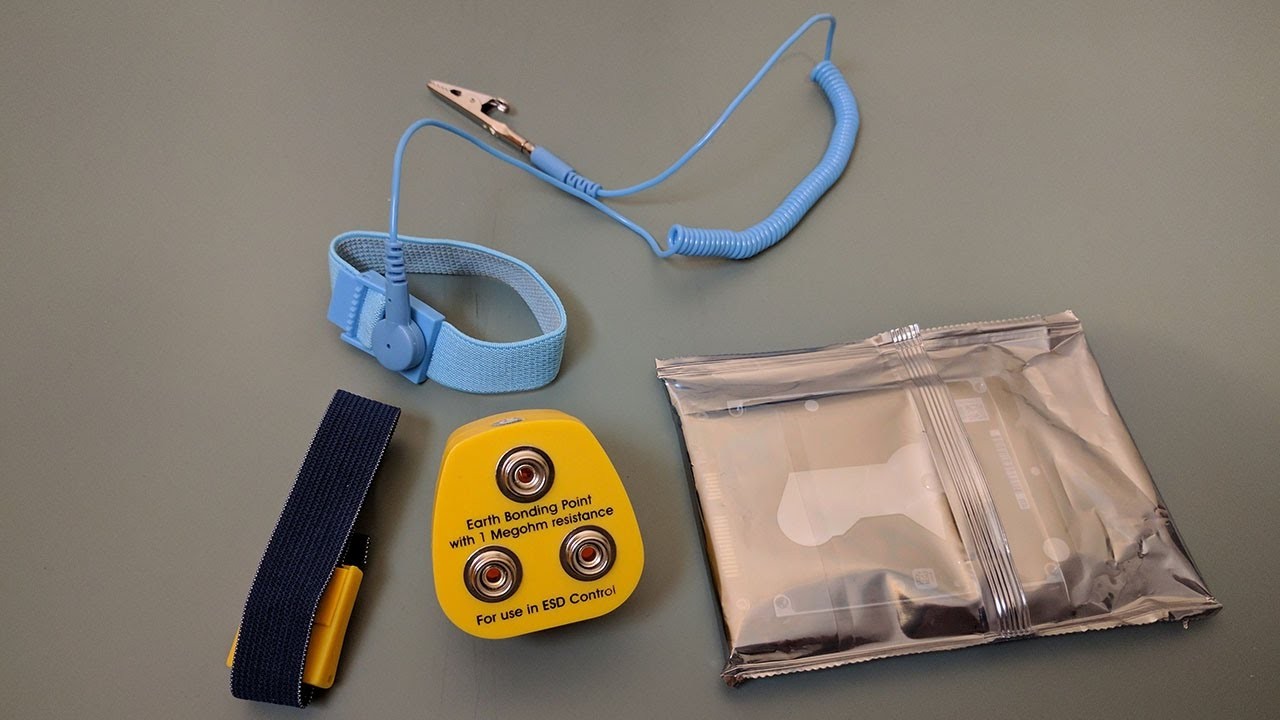

Electrostatic discharge is the transfer of charge between two objects at different electrical potentials, and it can damage or destroy delicate electronic components such as semiconductors, integrated circuits, and microchips. ESD packaging refers to the materials and methods employed to prevent such discharges, ensuring the safe transportation and storage of sensitive electronic goods. ESD packaging products include bags, boxes, trays, bubble wraps, and foams, all designed to shield electronic components from harmful electrostatic charges.

As electronic devices become smaller and more complex, the need for highly effective ESD packaging has risen, driving advancements in packaging technologies and materials. Additionally, as the consumer electronics market grows, especially with the rising popularity of smartphones, wearables, and IoT devices, ESD protection has become a critical focus for manufacturers and suppliers.

Recent Developments in the Electrostatic Discharge Packaging Market:

Technological Advancements: One of the key developments in the ESD packaging market is the ongoing advancement in materials. Manufacturers are constantly innovating to create new materials that offer enhanced electrostatic protection while also being cost-effective and environmentally friendly. New formulations of conductive polymers, antistatic coatings, and static-dissipative plastics are being introduced to provide better shielding for sensitive components.

Sustainability Efforts: With the global focus on sustainability, the ESD packaging industry is shifting toward more eco-friendly solutions. Packaging materials made from recyclable plastics, biodegradable materials, and sustainable alternatives to traditional packaging options are increasingly in demand. Companies are working to reduce their carbon footprint while maintaining the integrity and functionality of their products. The emphasis on sustainable ESD packaging is also driven by changing regulations in various regions, such as the European Union's regulations on plastic waste reduction.

Customization and Smart Packaging: Another noteworthy trend is the development of customized ESD packaging solutions. Different electronic components require varying levels of protection, and manufacturers are responding by providing tailored packaging solutions. Smart packaging, which integrates sensors and RFID technology, is also gaining traction. These smart solutions allow for real-time tracking of packages, ensuring that components are handled and stored properly to avoid any damage due to electrostatic discharge.

Increased Demand from Emerging Markets: The rapid growth of the electronics sector in emerging markets, especially in Asia-Pacific, is driving the demand for ESD packaging. As countries such as China, India, and South Korea increase their manufacturing capacities for electronics, there is a greater need for robust packaging solutions to safeguard electronic components from potential damage. Moreover, the adoption of ESD packaging in these regions is likely to rise as manufacturers seek to meet international standards of product quality and safety.

Growth in the Automotive and Aerospace Sectors: The automotive and aerospace industries have been increasingly adopting ESD packaging due to the growing use of electronic components in vehicles and aircraft. As more advanced electronic systems such as autonomous driving, infotainment systems, and in-flight electronics are integrated into these industries, the need for ESD protection continues to grow. ESD packaging solutions in these sectors ensure that delicate components remain undamaged during transportation and handling, improving the overall safety and reliability of end-products.

Conclusion:

The electrostatic discharge packaging market is evolving rapidly to meet the growing demand for safe and reliable packaging solutions in the electronics, automotive, and aerospace industries. With innovations in materials, sustainability initiatives, and customized packaging solutions, the market is well-positioned for continued growth. As industries continue to embrace technology, the role of ESD packaging in protecting critical electronic components will remain vital. Companies that can stay ahead of these trends and offer innovative, eco-friendly solutions will be well-positioned to succeed in the competitive market.