The Wrap Around Cartoners Market, an essential segment of the packaging industry, has experienced significant growth in recent years due to its applications across various sectors, including food, beverages, pharmaceuticals, and consumer goods. However, despite the favorable market dynamics, there are a number of challenges and restraints that could potentially hinder the market’s expansion. These restraints stem from both external factors, such as economic conditions, and internal operational complexities, such as technological limitations and regulatory issues. Understanding these market constraints is vital for manufacturers, investors, and stakeholders to navigate the current market landscape effectively.

1. High Capital Investment and Operational Costs

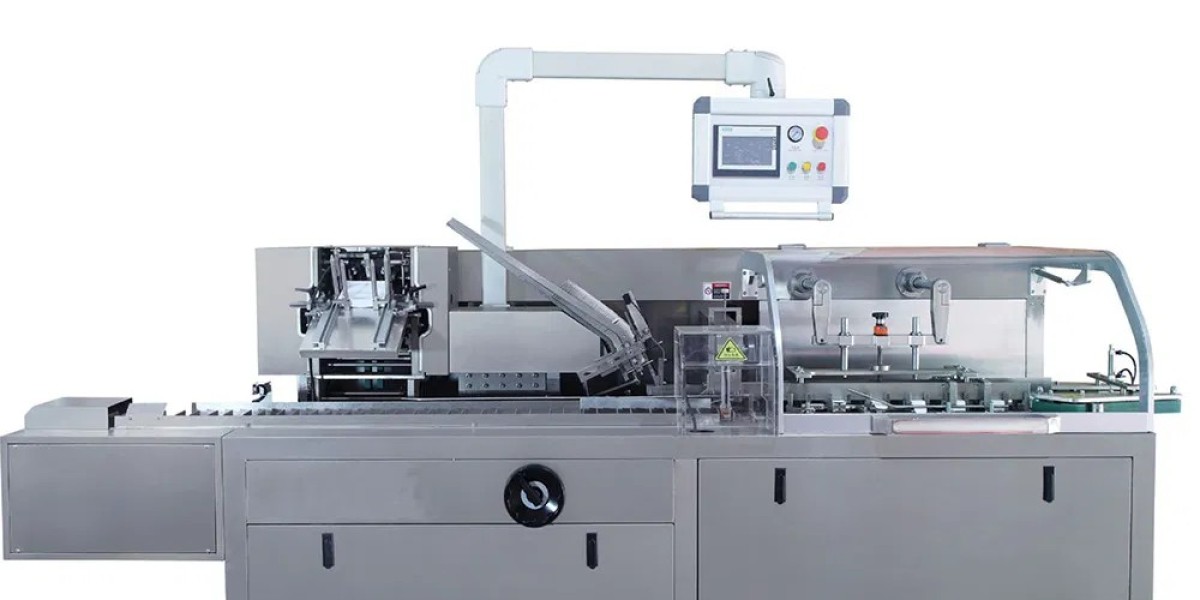

One of the primary restraints faced by the wrap around cartoners market is the high capital investment required to purchase and maintain advanced machinery. These cartoning systems, which require precision engineering and cutting-edge automation technologies, often come with a substantial upfront cost. For smaller players or new entrants, the financial barrier can be prohibitive, limiting their ability to compete with established firms that already have the necessary resources.

The operational costs associated with running these machines are considerable. These systems demand regular maintenance, and downtime for repairs can be expensive and time-consuming, further driving up costs. In addition to the initial investment and operational costs, the complex nature of wrap around cartoning machinery necessitates skilled labor, which may add to the overall expenditure.

2. Technological Limitations

While wrap around cartoning systems are designed for efficiency and versatility, they are not without their technological limitations. Some of the more traditional cartoners can be less adaptable to changes in product designs or packaging requirements. As packaging formats become increasingly diversified and customized to meet evolving consumer demands, some older machines struggle to accommodate such flexibility.

The growing emphasis on automation and smart manufacturing in the packaging industry requires cartoning solutions that integrate seamlessly with other automated processes, such as sorting, labeling, and palletizing. Many existing wrap around cartoning machines still lack the sophistication and adaptability required to operate in highly automated environments, leading to inefficiencies.

Manufacturers that are unable to invest in cutting-edge technology risk falling behind competitors who can offer more advanced solutions, further exacerbating the technological gap within the market. As packaging requirements become more complex and varied, these technological constraints will continue to act as a bottleneck for market growth.

3. Stringent Regulatory Standards

Regulatory requirements within the packaging industry can create significant challenges for wrap around carton manufacturers. Different regions, such as North America, Europe, and Asia-Pacific, have varying regulations regarding packaging materials, environmental impact, and consumer safety. For instance, regulations surrounding the use of recyclable and eco-friendly materials are becoming increasingly stringent, pushing manufacturers to adapt their production processes and material choices.

For companies operating in multiple markets, compliance with different national and international standards can become a costly and time-consuming affair. Ensuring that the machinery adheres to these regulations often means investing in regular audits, certifications, and system upgrades. Additionally, the growing focus on sustainability puts pressure on packaging producers to find more efficient, eco-friendly alternatives to traditional materials used in wrap around cartoning systems.

This need to meet environmental standards while maintaining product safety and quality can limit the flexibility of manufacturers, resulting in delays or increased production costs. Such regulatory hurdles can deter small and mid-sized companies from entering the market, as they may not have the resources to manage these complexities.

4. Supply Chain Disruptions and Material Shortages

The global supply chain has faced substantial disruptions in recent years, and the packaging sector has not been immune to these challenges. Raw materials needed for producing wrap around cartons, such as corrugated cardboard and plastic films, have at times been in short supply, driving up prices. Supply chain issues, from the procurement of materials to the transportation of finished goods, can significantly affect production timelines and lead to delays in meeting customer demands.

Fluctuations in the availability and cost of raw materials can also impact the overall profitability of manufacturers, particularly if they are locked into long-term contracts with suppliers. Furthermore, global economic uncertainties and geopolitical tensions can exacerbate these challenges, adding another layer of risk to the market.

5. Intense Competition and Price Pressure

The wrap around cartoners market is highly competitive, with numerous players vying for market share. The competition is not only from traditional packaging companies but also from new entrants offering lower-cost alternatives or specialized solutions. This intense competition often results in price pressure, with manufacturers being forced to lower prices to remain competitive.

As a result, companies may find it difficult to maintain profit margins while dealing with rising operational and material costs. This is especially challenging for smaller companies that may not have the scale or resources to compete with larger, more established firms. The price sensitivity of customers, combined with the increasing need for cost-effective solutions, can act as a significant constraint for the market.