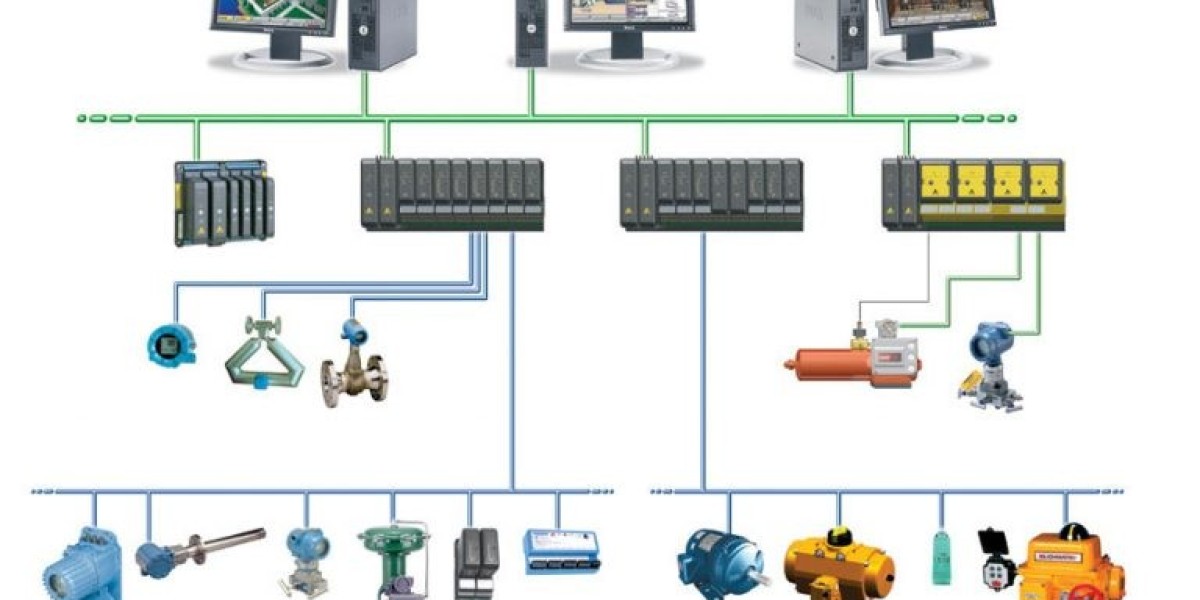

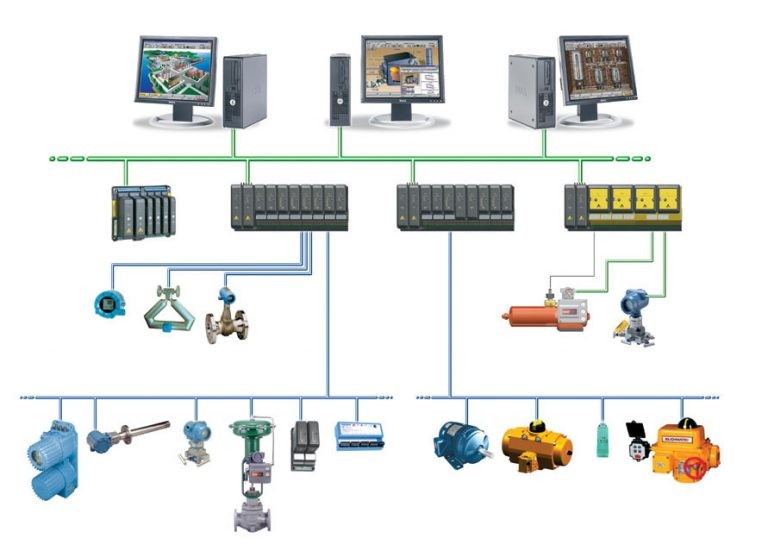

The Distributed Control Systems market is currently undergoing a rapid transformation, driven by advancements in technology, growing industrial automation, and the increasing need for efficient, scalable solutions in complex operations. A DCS is a control system used to manage industrial processes across various sectors, from oil and gas to pharmaceuticals, chemical manufacturing, and power generation. It provides real-time monitoring, control, and automation, ensuring smoother operations, reduced downtime, and optimized production.

1. Adoption of Industry 4.0 and Smart Manufacturing

The rise of Industry 4.0 and smart manufacturing has been a major catalyst in the expansion of the DCS market. The increasing integration of IoT (Internet of Things), artificial intelligence (AI), and machine learning (ML) into industrial processes has shifted control systems toward more autonomous, data-driven solutions. DCSs, equipped with AI and real-time data analytics, are allowing for enhanced decision-making, predictive maintenance, and the automation of complex processes that were previously handled manually or with basic control systems.

Industry 4.0 focuses on real-time data capture, remote monitoring, and cloud-based systems, all of which integrate seamlessly with DCS. As manufacturing and production facilities become more automated, the need for sophisticated control systems has surged. DCSs offer manufacturers an effective solution to streamline operations, reduce costs, and improve safety by monitoring systems more effectively.

2. Demand for Energy Efficiency and Sustainability

With global pressures to reduce carbon footprints and embrace sustainable practices, industries are increasingly turning to automated control systems to optimize energy consumption and improve operational efficiency. DCS technology plays a key role in helping companies monitor energy usage, predict energy demand, and identify areas for improvement.

In the energy sector, for example, power plants rely heavily on DCS to monitor processes and ensure that the plants operate at peak efficiency, reducing waste and emissions. As sustainability goals become more stringent, the DCS market is set to grow as industries across sectors seek to meet their environmental targets while maintaining productivity.

3. Increased Investment in Industrial Automation

The growing need for automation to enhance productivity, reduce human error, and maintain consistent product quality is another key driver in the DCS market. Industries, including oil and gas, chemicals, and food and beverage, are investing heavily in automation to enhance operational efficiency and reduce labor costs.

DCS systems help industries manage vast amounts of complex, distributed control in environments where human intervention can be inefficient, costly, or dangerous. From process control to data integration, DCS technology simplifies tasks that require high precision, making it essential in industries that require continuous, uninterrupted operations.

4. Technological Advancements in DCS Systems

The advancement of core technologies such as cloud computing, cybersecurity, and artificial intelligence is enabling the development of next-generation DCS platforms. Cloud-based DCS solutions, for instance, offer scalability, ease of maintenance, and enhanced security features, while AI and machine learning can be leveraged for predictive maintenance, anomaly detection, and optimizing overall performance.

Furthermore, the introduction of new hardware and software architectures, such as modular and decentralized control units, is improving the reliability and flexibility of DCS systems. These innovations allow for easier upgrades, seamless integration with existing systems, and faster response times to emerging industrial challenges.

5. Rising Adoption of Remote Monitoring and Control

The COVID-19 pandemic underscored the importance of remote monitoring and control systems, especially in industries where operational continuity was vital despite restrictions on physical presence. Remote monitoring enabled by DCS platforms allows operators to manage processes from anywhere, ensuring that production systems can continue to run smoothly even during unforeseen disruptions.

This trend of remote control is likely to continue as industries prioritize resilience and business continuity in the face of future challenges, driving continued growth in the DCS market.

6. Industry-Specific Customization

Another significant driver in the DCS market is the increasing customization of systems for specific industries. Different sectors require tailored control solutions to meet their unique demands. For example, the oil and gas sector requires systems with high reliability and real-time monitoring capabilities, while the pharmaceutical industry demands precision in batch processes to ensure product quality and compliance with regulatory standards.

By offering highly specialized DCS solutions, vendors are able to cater to the unique needs of different industries, making these systems even more indispensable for operational success.

Conclusion

The Distributed Control Systems market is growing rapidly, with numerous accelerators pushing the industry toward greater innovation and widespread adoption. As industries continue to focus on automation, sustainability, energy efficiency, and resilience, DCS technologies will remain at the core of operational success. With technological advancements, customizations for specific industries, and the rise of remote monitoring and AI, the future of DCS is promising, and it will likely play an even more significant role in industrial control systems globally.