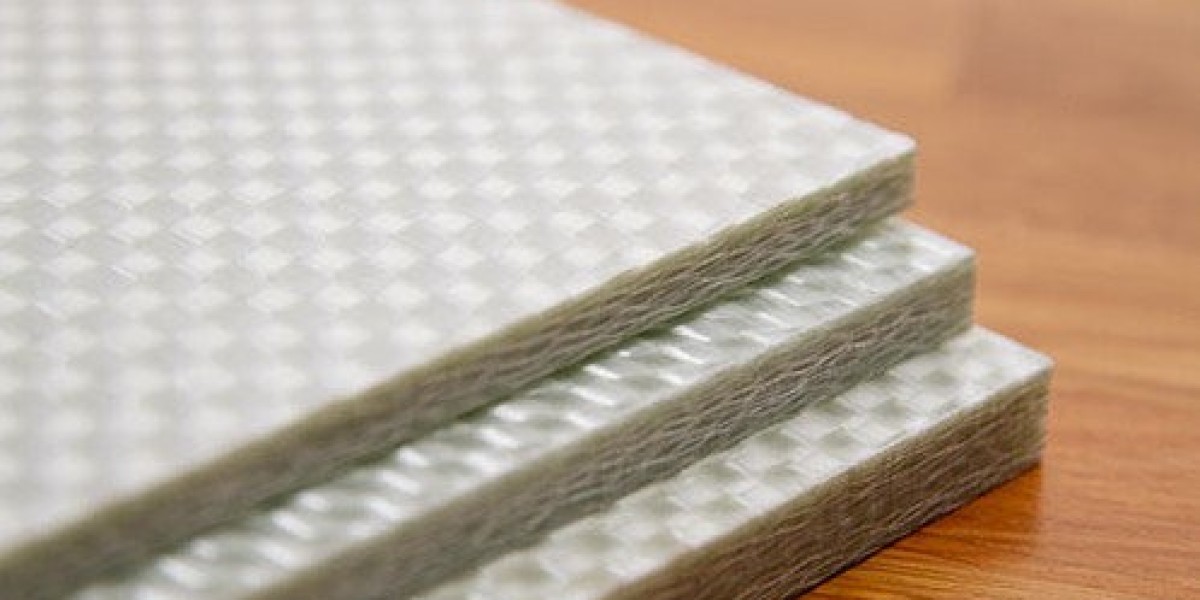

The bullet resistant fiberglass panels market is undergoing significant shifts due to evolving technological advancements, fluctuating global demand, and the increasing need for safety across diverse sectors. As industries adapt to security challenges, market disruptions play a pivotal role in shaping production strategies, pricing, and material innovation. This article delves into the primary factors contributing to these disruptions and their implications for manufacturers and end-users alike.

Key Market Disruptions

1. Raw Material Supply Challenges

- Fiberglass production relies on the availability of specialized raw materials, which are subject to global supply chain fluctuations.

- Trade restrictions, geopolitical tensions, and environmental regulations impact material availability and cost.

- Manufacturers are investing in alternative sourcing strategies to mitigate these risks.

2. Technological Advancements

- Innovations in composite material technology have enhanced panel performance, but they increase research and development costs.

- The integration of multi-layered designs for higher ballistic resistance is disrupting traditional manufacturing processes.

- Competitive pressure to adopt cutting-edge technologies is driving market evolution.

3. Economic Volatility

- Currency fluctuations and inflation directly affect the cost of importing raw materials and exporting finished products.

- Economic instability in key markets influences demand patterns, particularly in cost-sensitive regions.

4. Changing Safety Standards

- Evolving safety regulations worldwide demand frequent updates in panel design and production processes.

- Manufacturers face challenges in meeting differing compliance standards across regions.

5. Competition from Substitutes

- Alternatives such as ballistic steel and polycarbonate panels challenge fiberglass panels due to their specific advantages in cost and durability.

- Continuous innovation is required to maintain a competitive edge in this landscape.

Impact of Market Disruptions

1. Increased Costs

- Disruptions in raw material availability and regulatory compliance lead to higher production costs.

- End-users, especially in price-sensitive markets, face affordability challenges.

2. Market Fragmentation

- Emerging players with niche expertise are entering the market, creating a fragmented competitive landscape.

- Established companies are focusing on consolidation to sustain market share.

3. Shift in Demand Patterns

- Government and defense sectors remain stable consumers, while commercial adoption sees variability based on regional economic conditions.

- Residential applications are gaining traction as awareness of safety solutions grows.

4. Global Trade Dynamics

- Dependence on international supply chains makes the market vulnerable to global trade policies and logistical delays.

- Manufacturers are exploring localized production models to counteract trade disruptions.

Strategic Responses to Disruptions

1. Investment in R&D

- Companies are prioritizing investments in advanced material technology to improve performance and reduce costs.

- Collaboration with research institutions for next-generation panel designs is gaining momentum.

2. Diversification of Supply Chains

- Establishing multi-supplier agreements and sourcing from local markets reduce dependency on a single supply chain.

- Adoption of digital tools for supply chain management ensures better forecasting and risk mitigation.

3. Sustainability Initiatives

- The focus on eco-friendly production methods addresses regulatory pressures and appeals to environmentally conscious customers.

- Recycling and repurposing initiatives for fiberglass materials are emerging as sustainable practices.

4. Geographic Expansion

- Expanding operations to underserved markets, especially in Asia-Pacific and Africa, helps offset stagnation in mature regions.

- Strategic partnerships with local distributors and contractors enhance market penetration.

5. Customization and Flexibility

- Offering tailored solutions for specific industries, such as banking, retail, and transportation, boosts competitive positioning.

- Modular panel systems cater to evolving architectural and design preferences.

Future Outlook

The bullet resistant fiberglass panels market is poised to navigate these disruptions through innovation, strategic adaptability, and collaboration across the value chain. While challenges remain, such as cost pressures and competition, the industry's resilience and commitment to safety solutions ensure sustained growth in the coming years.