The automotive plastics market has become a significant force in the evolution of the automotive industry. As automakers continue to innovate, the demand for lightweight, durable, and cost-efficient materials has led to the increased adoption of plastics in vehicle manufacturing. The shift towards plastic components is not just about enhancing performance but also aligning with modern trends of sustainability and cost reduction.

Over the past few decades, automotive plastics have emerged as a viable alternative to traditional metals, thanks to their lighter weight and ability to reduce the overall weight of vehicles. As automakers strive to improve fuel efficiency and reduce carbon emissions, plastics play a pivotal role in meeting these objectives. Lighter vehicles consume less fuel, leading to better mileage and fewer emissions, which are critical factors in complying with stricter environmental regulations worldwide.

One of the key drivers of growth in the automotive plastics market is the growing emphasis on environmental sustainability. Automakers are increasingly using recycled and bio-based plastics to create eco-friendly alternatives to traditional materials. This shift is not only helping reduce the carbon footprint of the automotive industry but also tapping into a growing consumer demand for sustainable products. As regulations on emissions become more stringent, the need for energy-efficient vehicles drives innovation in material science, with plastics standing out as a versatile, low-emission material.

In addition to sustainability, cost efficiency is another crucial factor influencing the adoption of plastics in automotive manufacturing. The manufacturing of plastic parts is often less expensive than that of metal counterparts, contributing to reduced overall production costs. Automakers, especially in the current economic landscape, are focused on minimizing costs while maintaining high performance and quality. Plastics offer the flexibility to create complex shapes and designs at a lower cost, further enhancing their appeal in the competitive automotive market.

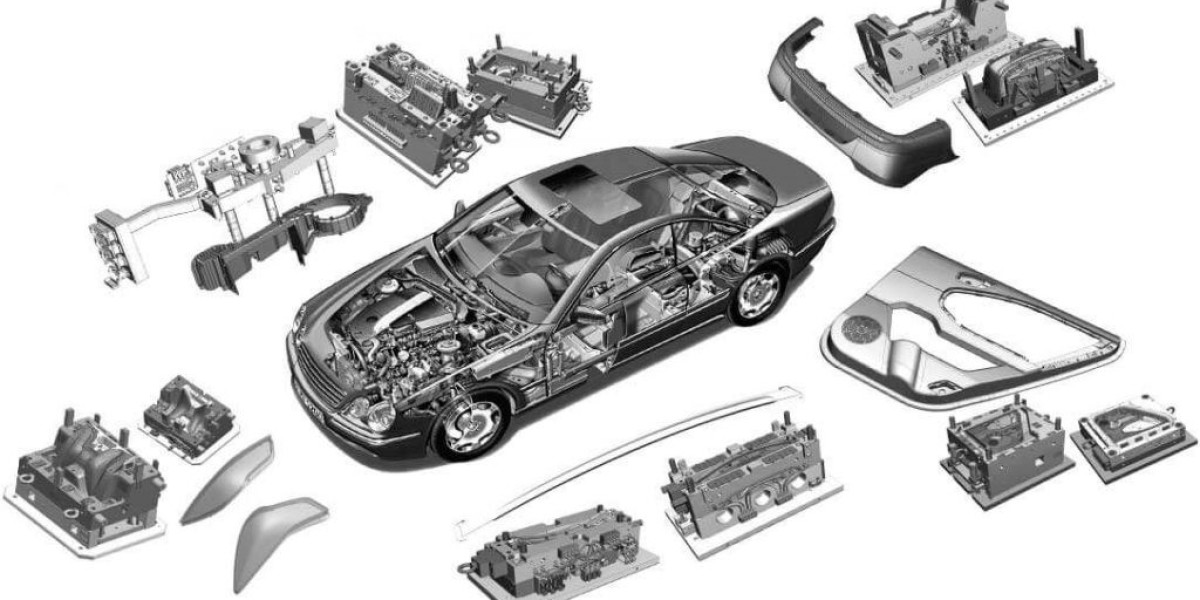

The versatility of automotive plastics is another driving force behind their growth. Plastics are used across a wide range of applications, from exterior components like bumpers, fenders, and grilles to interior elements such as dashboards, seats, and door panels. In addition, plastics are playing a critical role in the development of advanced electric and hybrid vehicles, where lightweight materials are essential to maximize battery efficiency and vehicle range.

With the rise of electric vehicles (EVs), the demand for automotive plastics is expected to grow significantly. EVs require lighter components to increase battery efficiency and driving range, which positions plastics as an essential material in the manufacturing of these vehicles. The integration of lightweight plastics in electric vehicles contributes to reducing energy consumption, ultimately improving the vehicle's performance and extending its battery life.

Another trend driving the automotive plastics market is the increasing use of advanced plastics like polycarbonate, polypropylene, and thermoplastic elastomers. These materials offer enhanced strength, flexibility, and resistance to heat and chemicals, making them suitable for a wide range of automotive applications. Additionally, advancements in manufacturing technologies, such as 3D printing, are allowing for more precise and customized plastic components, further expanding the potential applications of plastics in automotive design.

The growing focus on vehicle aesthetics is also playing a role in the expanding use of plastics. With the automotive industry’s increasing emphasis on design and consumer preferences for visually appealing vehicles, plastics offer the ability to create sleek, modern designs with enhanced finish quality. Plastic parts can be molded into intricate shapes and patterns, allowing automakers to meet consumer expectations for both functional and stylish vehicles.

As the market for automotive plastics continues to expand, manufacturers are also investing heavily in research and development to improve the performance and functionality of these materials. The evolution of materials science has enabled the creation of plastics that are not only lightweight but also possess greater strength, heat resistance, and durability, addressing the needs of modern automotive engineering.