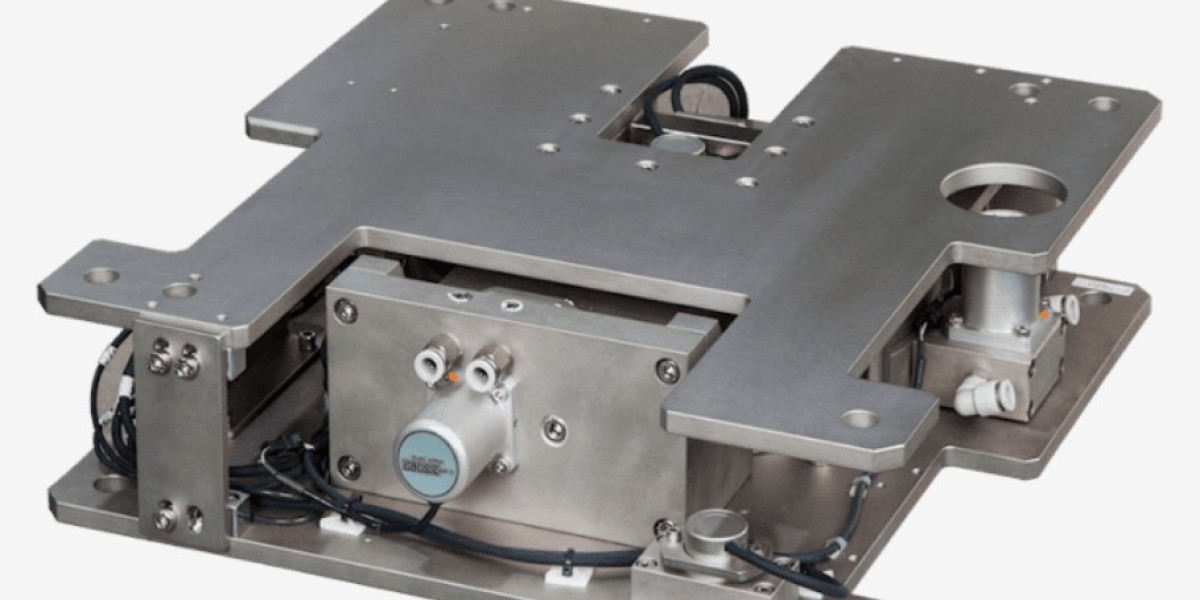

The vibration control system market has grown significantly in recent years due to the increasing demand for improved equipment performance, durability, and safety across various industries. Vibration control systems are essential for minimizing or eliminating unwanted vibrations in machinery, vehicles, and structures, ensuring operational efficiency, reducing wear and tear, and enhancing overall user comfort. This technology plays a critical role in sectors like automotive, aerospace, industrial machinery, and construction, where the need to control vibrations is paramount for safety, quality, and long-term performance.

Key Drivers of the Vibration Control System Market

The primary factor driving the growth of the vibration control system market is the rapid technological advancements in industries such as automotive and aerospace. As vehicles and machinery become more complex, the need for efficient vibration control solutions has become more pronounced. In the automotive sector, for instance, vibration control systems help improve vehicle comfort and stability while reducing noise levels. This results in a better driving experience, which is crucial for manufacturers competing in an increasingly competitive market.

Another key driver is the rising focus on environmental sustainability and energy efficiency. Governments and regulatory bodies worldwide are introducing stricter regulations concerning emissions and energy consumption. Vibration control systems contribute by improving the efficiency of engines, machines, and infrastructure, thereby reducing energy wastage. The adoption of electric vehicles and the push towards greener technologies also emphasize the need for better vibration control systems to enhance performance while lowering environmental impact.

Moreover, the growing emphasis on safety in industrial environments is pushing companies to adopt vibration control technologies. Industrial machinery, especially in high-stress environments, can cause significant damage if vibration levels are not properly managed. These systems help reduce the risk of damage to equipment and ensure the safety of workers. In addition, they contribute to the longevity of machinery, which results in cost savings for businesses over time.

Challenges in the Vibration Control System Market

Despite the robust growth, the vibration control system market faces several challenges. One of the most significant hurdles is the high initial cost of installation. Advanced vibration control systems often require a substantial upfront investment, which can be a barrier for smaller businesses or those operating in cost-sensitive markets. Although the long-term benefits of these systems, such as reduced maintenance costs and improved operational efficiency, outweigh the initial investment, the high cost can still be an obstacle for widespread adoption.

Another challenge is the complexity of designing vibration control systems that can effectively manage vibrations across various environments. Different applications require customized solutions, and developing a system that meets the specific needs of each industry can be technically demanding. The integration of these systems into existing machinery or infrastructure without disrupting operations can also be challenging. Additionally, the need for skilled professionals to install and maintain these systems further adds to the overall cost.

Furthermore, the vibration control system market is also pressured by competition from alternative technologies. While vibration control systems are widely used, alternatives such as shock absorbers or passive damping systems are often seen as more cost-effective or simpler solutions. These alternatives can sometimes offer similar benefits at a lower cost, which forces vibration control system manufacturers to continuously innovate and improve their products to stay competitive.

Competitive Pressures in the Vibration Control System Market

Competition within the vibration control system market is fierce, as companies strive to develop more efficient, cost-effective, and technologically advanced solutions. To maintain a competitive edge, manufacturers are focusing on research and development, seeking new materials and innovative designs to improve system performance. Companies are also investing in automation and digitalization, incorporating smart sensors and IoT connectivity into vibration control systems. These advancements allow for real-time monitoring and adjustment of vibration levels, resulting in more precise and efficient operations.

Another key factor influencing competition is the global nature of the market. With manufacturers from different regions competing for market share, companies need to adapt to varying regional needs and regulatory environments. This requires a high degree of flexibility and the ability to quickly respond to changing market dynamics. Furthermore, partnerships and collaborations between businesses, research institutions, and government agencies are becoming increasingly common as companies work together to push the boundaries of vibration control technology.

Conclusion

The vibration control system market is poised for continued growth, driven by technological innovations, regulatory pressures, and the increasing need for safety, efficiency, and comfort in various industries. While challenges such as high installation costs and competition from alternative solutions remain, ongoing advancements in system design and integration are likely to overcome these barriers. As industries continue to evolve, the role of vibration control systems will become even more critical, ensuring optimal performance and safety across diverse applications.