The Conductive Polymer Coating Market is witnessing significant expansion due to the increasing demand for advanced materials that offer both electrical conductivity and flexibility. Conductive polymer coatings combine the benefits of traditional conductive materials like metals with the versatility and lightweight nature of polymers, creating a wide range of opportunities for their use across various industries. From electronics to automotive, aerospace, and healthcare, these coatings are playing a pivotal role in driving technological innovation and improving the performance of many devices and applications. This article explores the key factors contributing to the expansion of the conductive polymer coating market and the industries driving its growth.

1. Rising Demand for Electronics and Wearables

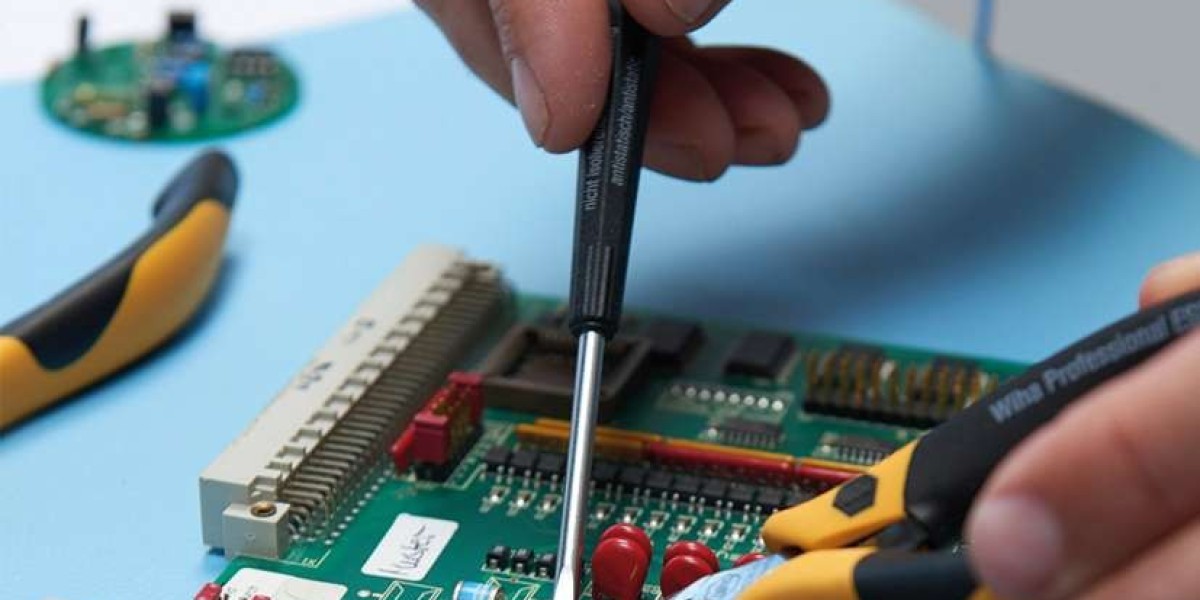

One of the most prominent drivers of the conductive polymer coating market expansion is the growing demand for electronic devices and wearable technology. As the world becomes more connected, there is an increasing need for flexible, lightweight, and durable materials for the development of smart electronics, including smartphones, tablets, wearables, and flexible displays. Conductive polymer coatings enable the production of flexible printed circuit boards (PCBs), sensors, and electronic skins by providing electrical conductivity while maintaining the essential flexibility and durability required for these devices.

Furthermore, conductive polymer coatings are used in antistatic coatings to prevent static damage to sensitive electronics. These coatings are particularly important in the manufacturing of semiconductors, LEDs, and displays, where maintaining a safe, static-free environment is crucial for product performance. The rise of flexible electronics and the integration of conductive polymer coatings into this segment are significant contributors to the market's expansion.

2. Growth in Electric Vehicles and Automotive Electronics

The automotive industry, particularly the electric vehicle (EV) sector, is another key driver of the conductive polymer coating market. As the adoption of electric vehicles increases globally, the demand for advanced materials to improve battery performance, motor efficiency, and electromagnetic interference (EMI) shielding grows. Conductive polymer coatings are used to enhance the performance of automotive batteries, ensuring they are more energy-efficient and long-lasting. These coatings also play a role in corrosion protection, shielding components like motors, wiring, and battery packs from environmental damage such as moisture and salt.

Additionally, conductive polymer coatings are critical for protecting the electronic systems in modern vehicles. These coatings provide EMI shielding to ensure the smooth operation of essential systems, including navigation, communication, and safety features, by preventing the interference caused by electromagnetic radiation.

3. Aerospace and Defense Applications

The aerospace and defense sectors also significantly contribute to the growth of the conductive polymer coating market. In aerospace, there is an increasing need for lightweight, corrosion-resistant, and high-performance materials to improve the durability and efficiency of aircraft and spacecraft. Conductive polymer coatings offer excellent protection against corrosion caused by extreme conditions such as high humidity and saltwater exposure. This is crucial for components such as aircraft wings, fuel systems, and engine parts.

Furthermore, conductive polymer coatings are employed in EMI shielding applications to protect sensitive aerospace electronics from external interference. Navigation systems, radar systems, and communication devices rely on the effective use of EMI shielding to function properly in the high-stakes environment of aerospace operations.

4. Healthcare and Medical Devices

In the healthcare industry, conductive polymer coatings are increasingly being used in the development of medical devices, particularly wearable health monitors, biosensors, and implantable medical devices. These coatings provide electrical conductivity, biocompatibility, and flexibility, making them ideal for use in health-monitoring devices that need to remain in contact with the skin for extended periods.

For instance, biosensors that monitor biological signals like heart rate or blood glucose levels require conductive coatings for efficient signal transmission. Conductive polymers ensure that these devices function accurately and reliably, improving patient care through continuous health monitoring. The flexibility and comfort provided by these coatings make them particularly suitable for wearable medical technologies, enabling prolonged use without discomfort.

5. Environmental Sustainability and Cost-Effectiveness

As industries and governments become more focused on sustainability and reducing environmental impact, the demand for eco-friendly conductive polymer coatings is also on the rise. Conductive polymer coatings are generally more environmentally friendly than traditional conductive materials like metals, as they can be produced using less energy and raw materials. The use of renewable resources for polymer production is also gaining attention, making these coatings a sustainable option for manufacturers seeking to reduce their carbon footprint.

Additionally, conductive polymer coatings are more cost-effective than traditional metallic coatings, providing a more affordable alternative for industries looking to reduce material costs. This cost-effectiveness, combined with their lightweight and flexible properties, makes conductive polymer coatings an attractive choice for industries such as electronics, automotive, and aerospace.

Conclusion

The conductive polymer coating market is experiencing substantial expansion, driven by technological advancements and the increasing demand for lightweight, flexible, and durable materials. With applications spanning electronics, automotive, aerospace, healthcare, and more, conductive polymer coatings are at the forefront of driving innovation across various industries. As the need for sustainable, cost-effective, and high-performance materials grows, the demand for conductive polymer coatings will continue to rise, fueling market expansion and creating new opportunities for growth in the years to come.